What Are the Advantages of a High-Speed Clock?

Jun 25, 2025

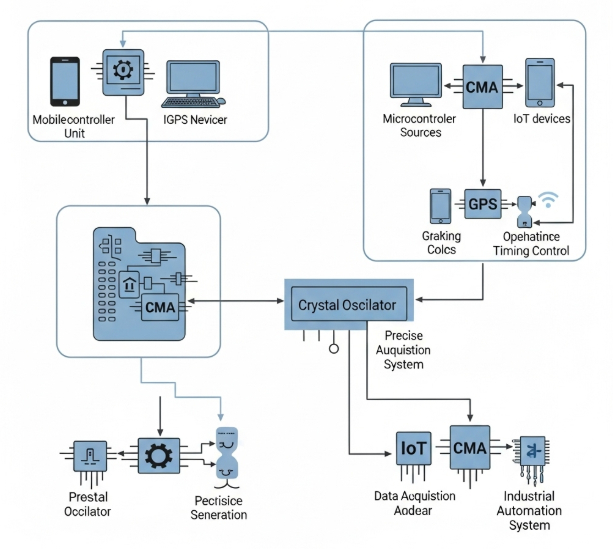

In the world of advanced electronics and industrial automation, the demand for precise control and rapid data processing has led to a growing reliance on high speed clocks. These timing sources, often realized through crystal oscillators, are fundamental in enabling modern systems to function with accuracy and consistency. In particular, high speed clock signals are essential in applications such as precision motors, including servo motors and brushless DC motors (BLDC), where real-time control and synchronization are critical.

The Imperative of High-Frequency Control in Precision Motors

Precision motors are the workhorses of industries ranging from robotics and automation to medical devices and aerospace. Their ability to achieve precise movements, maintain stable speeds, and rapidly respond to commands is directly tied to the quality and frequency of their control signals. For servo motors, renowned for their closed-loop feedback systems, a high-frequency clock enables faster sampling rates of positional feedback, leading to more immediate error correction and smoother, more accurate motion. Imagine a robotic arm needing to place a tiny component with sub-millimeter accuracy; any delay in processing feedback or issuing corrective commands could lead to significant errors. A higher clock speed minimizes these latencies, allowing the servo motor to constantly adjust its position with greater finesse.

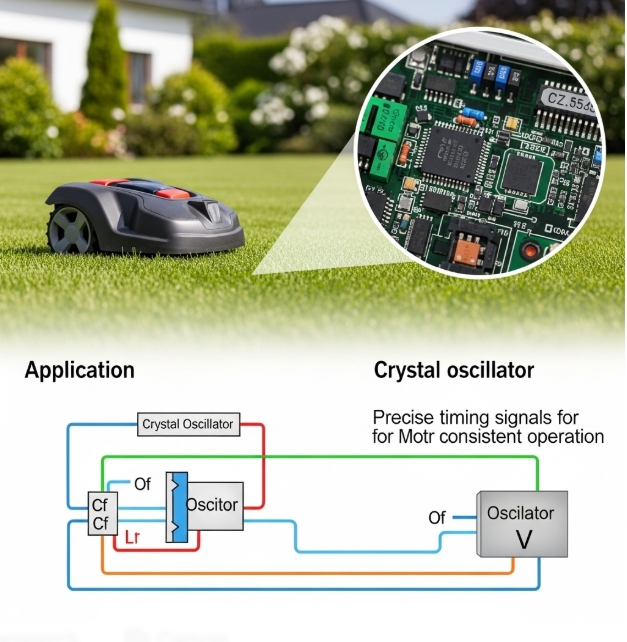

Similarly, BLDC motors, increasingly popular due to their efficiency and longevity, rely on precise electronic commutation. Unlike brushed motors, BLDCs use electronic controllers to switch the current in their windings, creating a rotating magnetic field that drives the rotor. The timing of these commutations is critical for optimal performance, efficiency, and torque ripple minimization. A high-speed clock allows the motor controller to generate these commutation signals with greater resolution and at a higher rate, leading to smoother torque delivery and more efficient operation. This improved control signal frequency also enhances the motor's ability to handle dynamic loads and sudden changes in demand, ensuring stable and reliable performance even in challenging environments. The ability to precisely control the phase currents at a much higher resolution due to a faster clock allows for advanced control algorithms to be implemented, further enhancing the motor’s performance and energy efficiency.

Furthermore, applications requiring real-time control and rapid data processing benefit immensely from elevated clock frequencies. Consider industrial automation systems where multiple motors are synchronized to perform complex tasks. A high-speed clock ensures that all control signals are issued with minimal temporal disparities, preventing desynchronization and maintaining the integrity of the automated process. This is not just about speed; it's about the responsiveness of the control system as a whole. Faster clocks contribute to a more deterministic system, where the timing of events is highly predictable, which is crucial for safety-critical applications and those requiring stringent performance guarantees.

The Unseen Hand: How Crystal Oscillators Shape System Stability

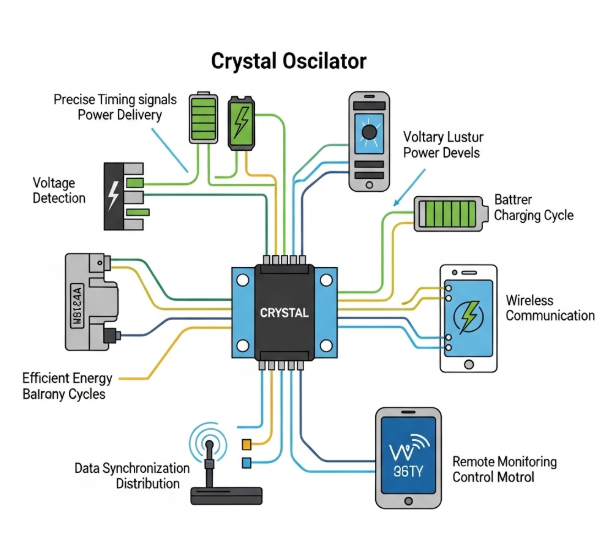

At the very heart of generating these critical clock signals lies the crystal oscillator. These tiny, often overlooked components are the unsung heroes responsible for providing the stable, accurate, and high-frequency timing pulses that every digital circuit needs. The performance of a crystal oscillator directly impacts the overall system stability and reliability. A poor-quality or unstable crystal can lead to timing errors, data corruption, and even system crashes, especially in demanding applications.

The frequency accuracy and frequency stability of a crystal oscillator are paramount. Frequency accuracy refers to how close the actual output frequency is to its specified value, while frequency stability describes how well the output frequency remains constant over time, temperature variations, and other environmental factors. In high-precision control systems, even minute deviations in the clock frequency can lead to accumulated errors, affecting the long-term performance of the motor or system. For instance, in a motor control unit, a drifting clock could cause inconsistencies in pulse width modulation (PWM) signals, leading to erratic motor behavior, increased vibrations, or reduced efficiency.

Moreover, the phase noise of a crystal oscillator is a critical parameter, particularly in applications involving communication or sensitive analog-to-digital conversions. Phase noise represents short-term fluctuations in the phase of a signal and can degrade the signal-to-noise ratio in communication systems or introduce jitter into digital signals. In the context of motor control, excessive phase noise could contribute to less precise timing of commutation events, leading to increased electromagnetic interference (EMI) or reduced motor efficiency. Therefore, selecting a crystal oscillator with low phase noise is crucial for maintaining signal integrity and optimal system performance.

The temperature stability of a crystal oscillator is another vital consideration. As ambient temperatures fluctuate, the resonant frequency of a crystal can drift. High-quality crystal oscillators are designed to minimize this drift, ensuring consistent performance across a wide operating temperature range. This is especially important for automotive applications or industrial equipment that may operate in harsh or uncontrolled environments. A stable clock source ensures that the motor control algorithms remain robust and accurate, regardless of external temperature variations.

In essence, the crystal oscillator acts as the fundamental time reference for the entire electronic system. Its stability directly translates to the reliability of digital communication, the precision of data acquisition, and ultimately, the accuracy of motor control. Investing in high-quality crystal oscillators, often characterized by their low jitter and high Q-factor, is not merely an option but a necessity for achieving predictable and repeatable system behavior, particularly when designing systems that demand the highest levels of performance and long-term reliability. The ability of the entire system to maintain synchronization across multiple components heavily relies on the rock-solid foundation provided by a stable clock.

Broader Implications of High-Speed Clocks

Beyond the immediate benefits for precision motors, the advantages of a high-speed clock permeate numerous other aspects of modern electronics. In general, a faster clock allows for more computational operations per unit of time, leading to higher processing throughput and faster execution of complex algorithms. This is evident in microcontrollers and digital signal processors (DSPs) used in various applications, from consumer electronics to high-performance computing. The ability to perform calculations more rapidly means that more sophisticated control strategies, such as field-oriented control (FOC) for BLDC motors, can be implemented with greater fidelity and responsiveness.

Furthermore, a high-speed clock facilitates faster data transfer rates between different components within a system. This is crucial for applications that involve significant data logging, real-time image processing, or high-bandwidth communication. In a system where data needs to be acquired, processed, and acted upon in milliseconds, the speed at which this information can flow is directly limited by the system clock. Higher clock speeds enable parallel processing capabilities and more efficient memory access, thereby reducing bottlenecks and improving overall system efficiency.

The concept of system latency is also directly impacted by clock speed. Latency refers to the delay between an input and a corresponding output. In any real-time system, minimizing latency is critical for responsiveness and control. A faster clock inherently reduces the time it takes for signals to propagate and for operations to complete, leading to a more responsive and interactive system. This is particularly noticeable in applications requiring immediate feedback, such as human-machine interfaces or robotic manipulation.

Ultimately, the drive towards higher clock speeds is a reflection of the increasing demand for more sophisticated, responsive, and precise electronic systems. While higher frequencies introduce challenges such as increased power consumption and electromagnetic compatibility (EMC) issues, the benefits in terms of performance, accuracy, and control often outweigh these considerations, particularly in the specialized domain of high-performance embedded systems and advanced motion control. The judicious selection and implementation of high-speed clocks and their underlying crystal oscillators are therefore fundamental design considerations for engineers striving to push the boundaries of what is possible in precision engineering.

In conclusion, the advantages of a high-speed clock extend far beyond merely making a system "faster." For precision motors like servo and BLDC motors, a high-frequency clock is indispensable for achieving the rapid, accurate, and stable control required for their optimal performance. Moreover, the stability and accuracy of the crystal oscillator, the source of these critical clock signals, profoundly influence the overall reliability and precision of the entire electronic system. As technology continues to advance and the demand for even greater precision and responsiveness grows, the significance of a robust and high-speed timing foundation will only continue to amplify, serving as the silent, yet essential, enabler of cutting-edge innovation.

Read More