What is the use of crystal oscillator in ultrasonic sensor?

Mar 06, 2025

Crystal oscillators are fundamental components in modern electronic systems, providing precise frequency control essential for stable and accurate operations. In the field of low-altitude economical UAVs (unmanned aerial vehicles), crystal oscillators play a critical role in maintaining communication, navigation, and control system reliability. Without a stable frequency source, UAVs risk experiencing performance fluctuations that could lead to navigation errors, unstable communication links, or inefficient power consumption.

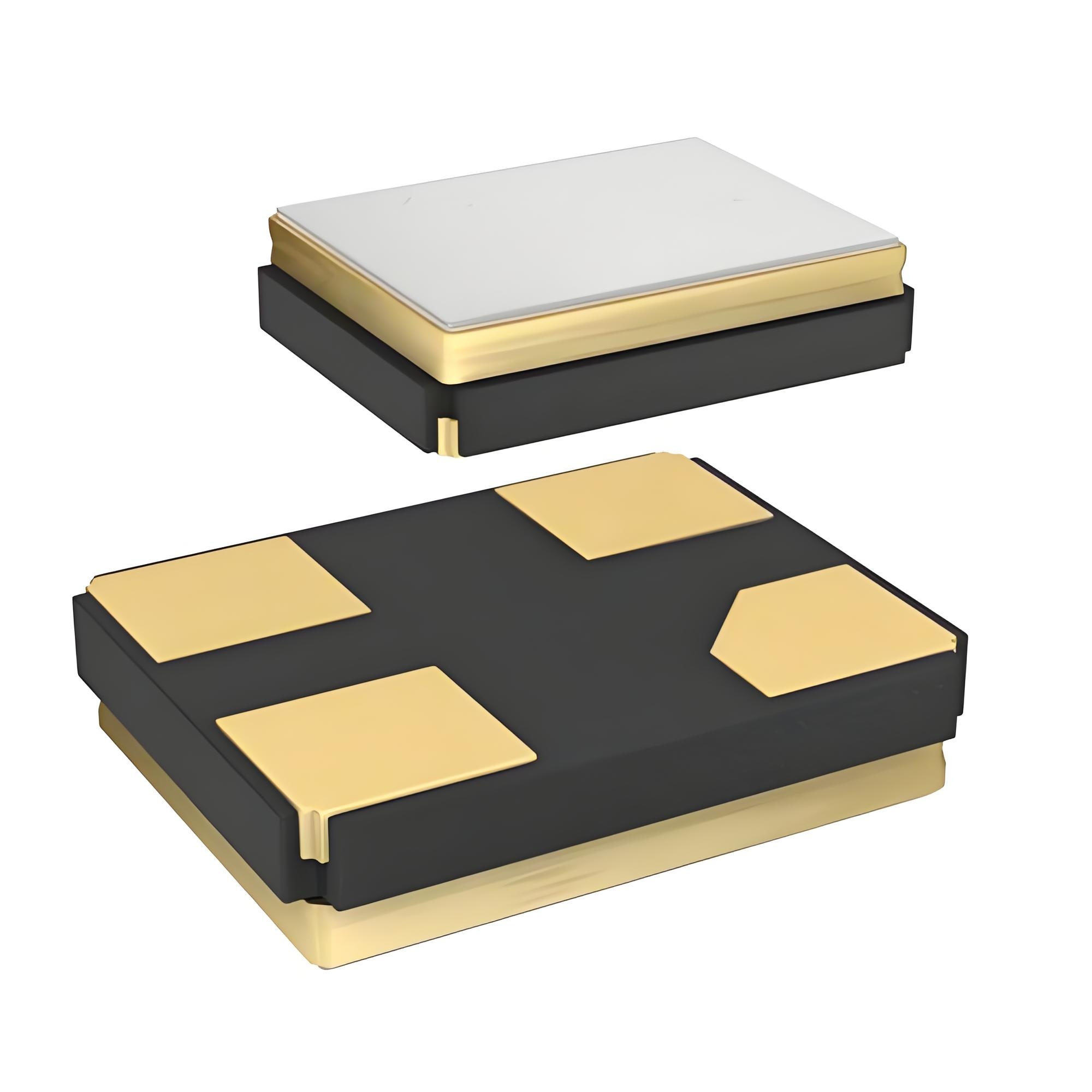

Among the different types of crystal oscillators, temperature-compensated crystal oscillators (TCXOs) are particularly important for UAV applications. JGHC’s W21 series of temperature-compensated crystal oscillators offer excellent frequency stability and low phase noise, ensuring consistent performance in various environmental conditions. With a compact size and a wide operating temperature range, the W21 series is well-suited for drones that need to maintain stable frequencies despite temperature variations.

Why Are Crystal Oscillators Essential in UAVs?

UAVs operate in dynamic environments where factors such as altitude, temperature, and electromagnetic interference can affect signal integrity. Crystal oscillators provide the precise timing needed to ensure that essential functions—such as GPS navigation, flight stabilization, and data transmission—remain accurate and reliable.

The W21 Crystal Oscillator is specifically designed to address these challenges, offering low power consumption and high durability. These characteristics are particularly valuable in logistics drones, micro drones, and entry-level multi-rotor drones, where battery efficiency and compact design are crucial.

Key Applications of Crystal Oscillators in UAVs

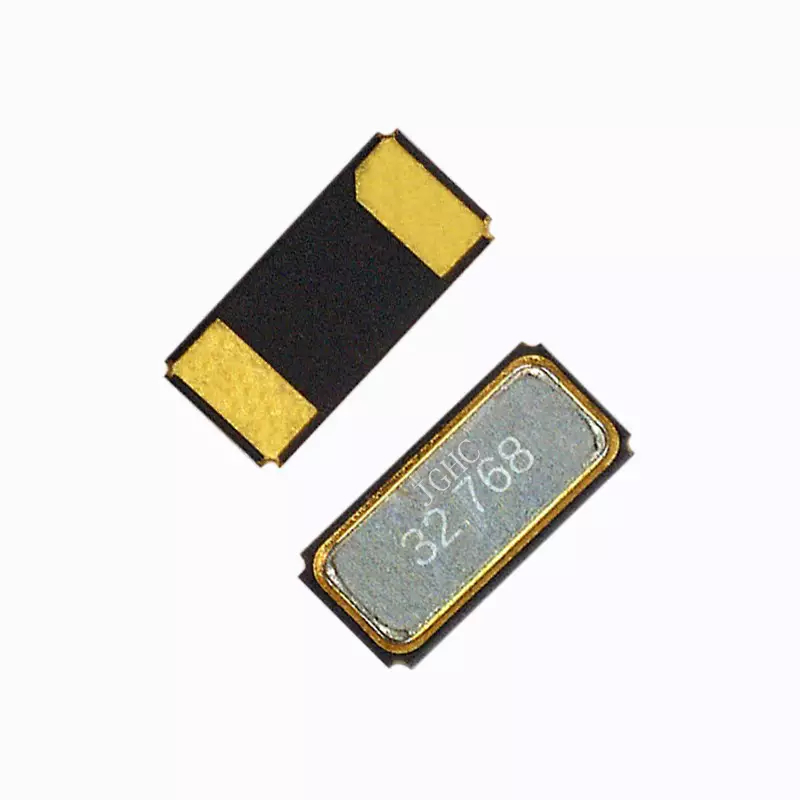

GPS Navigation and Timing Synchronization

GPS-based navigation is a core function in UAVs, enabling precise positioning and route planning. However, satellite signals are highly dependent on stable clock sources to maintain accurate timing.

W21 crystal oscillator with custom frequency ensures minimal frequency drift, which is crucial for GPS receivers to provide accurate location data. Any instability in timing signals can result in incorrect positioning, impacting the drone’s ability to follow pre-programmed flight paths or maintain its position in hovering mode.

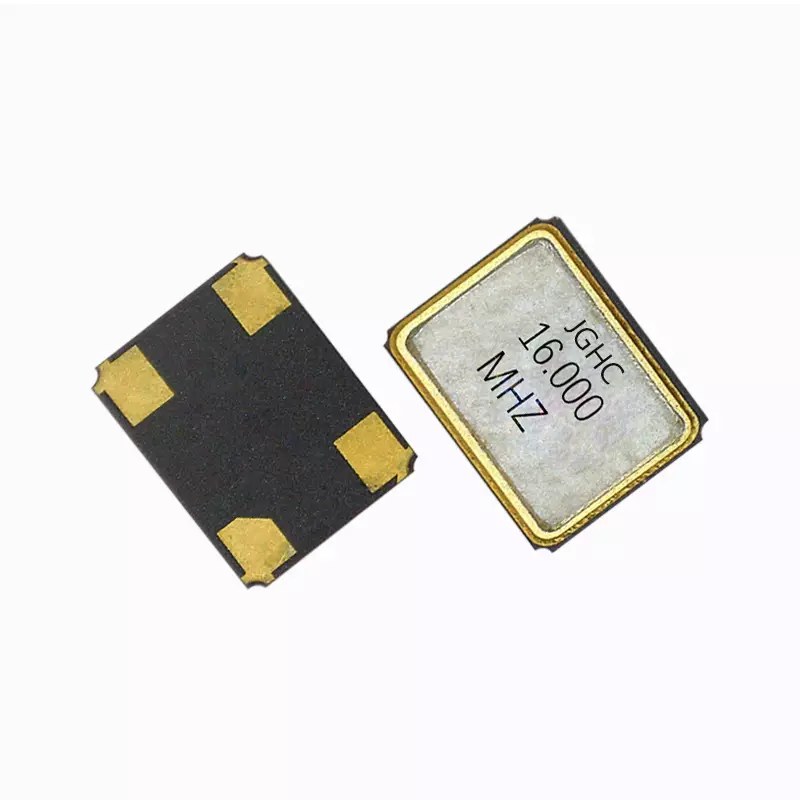

Wireless Communication and Remote Control Systems

UAVs rely on wireless communication systems to send and receive data from ground stations. These systems require highly stable frequencies to prevent signal degradation and interference, particularly in environments with multiple active radio sources.

Using a Custom W21 Crystal Oscillator Manufacture solution allows UAV developers to integrate precise oscillators into drone communication modules, ensuring seamless real-time control, telemetry data transmission, and video streaming without frequency drift.

Flight Control and Sensor Integration

Modern UAVs use advanced flight controllers that process data from multiple sensors, including gyroscopes, accelerometers, and barometers. These sensors rely on precise timing signals to function correctly, enabling smooth flight and accurate altitude adjustments.

The W21 crystal oscillator custom solution helps ensure that sensor data is processed with minimal latency, improving drone stability and responsiveness. This is especially beneficial for multi-rotor drones that need to quickly and accurately adjust flight stability.Power Management and Energy Efficiency.

Battery life is a critical concern in UAV design, as drones must optimize energy consumption to extend flight duration. The low power consumption of the W21 Crystal Oscillator contributes to efficient power usage, reducing the overall energy demand of onboard electronics.

By integrating an OEM ODM W21 Crystal Oscillator Solution, drone manufacturers can achieve optimized power management, extending the operational lifespan of UAVs without compromising performance.

Advantages of Using W21 Crystal Oscillators in UAVs

The W21 series temperature-compensated crystal oscillators offer several key advantages that make them ideal for UAV applications:

· High Frequency Stability – Ensures reliable operation under varying temperature conditions.

· Low Phase Noise – Reduces signal distortion in communication and navigation systems.

· Compact and Lightweight Design – Ideal for drones with strict size and weight constraints.

· Energy Efficiency – Extends battery life, improving UAV flight duration.

· Customizable Specifications – Allows for tailored frequency requirements, meeting different UAV needs.

For applications that require high-precision and stable timing, the reliable W21 crystal oscillator for drone systems provides powerful performance, ensuring that drones operate efficiently under various conditions.

Crystal oscillators are indispensable in UAV technology, supporting critical functions such as GPS navigation, flight control, communication systems, and power management. The W21 Crystal Oscillator series by JGHC offers high durability, excellent frequency stability, and low power consumption, making it a suitable choice for low-altitude economical UAVs.

By leveraging custom W21 crystal oscillator solutions, drone manufacturers can enhance the reliability and efficiency of their UAV systems, ensuring consistent performance even in challenging environments. Whether for logistics, surveillance, or industrial applications, integrating a high-quality oscillator like the W21 is a key step toward achieving stable, precise, and energy-efficient UAV operations.If you have any purchasing needs for this product, please contact our sales team or send your needs to ivy@jghcrystal.com. We will provide you with the most professional solutions.

Read More