How Accurate is a S32 Crystal Oscillator?

Oct 11, 2024

Crystal oscillators are essential components in modern electronics, and the S32 Crystal Oscillator stands out for its high precision and reliability. Whether in telecommunications, automotive systems, or consumer electronics, these oscillators ensure stable and accurate signal frequencies. But how accurate is the S32 Crystal Oscillator, and why is it the go-to solution for many high-demand applications?

A crystal oscillator generates a precise frequency signal by utilizing the mechanical resonance of a vibrating crystal, usually quartz. The quartz crystal within the oscillator vibrates at a specific frequency when subjected to an electric field. This oscillation is then used to generate a consistent, stable frequency, which is critical for timing in electronic circuits.

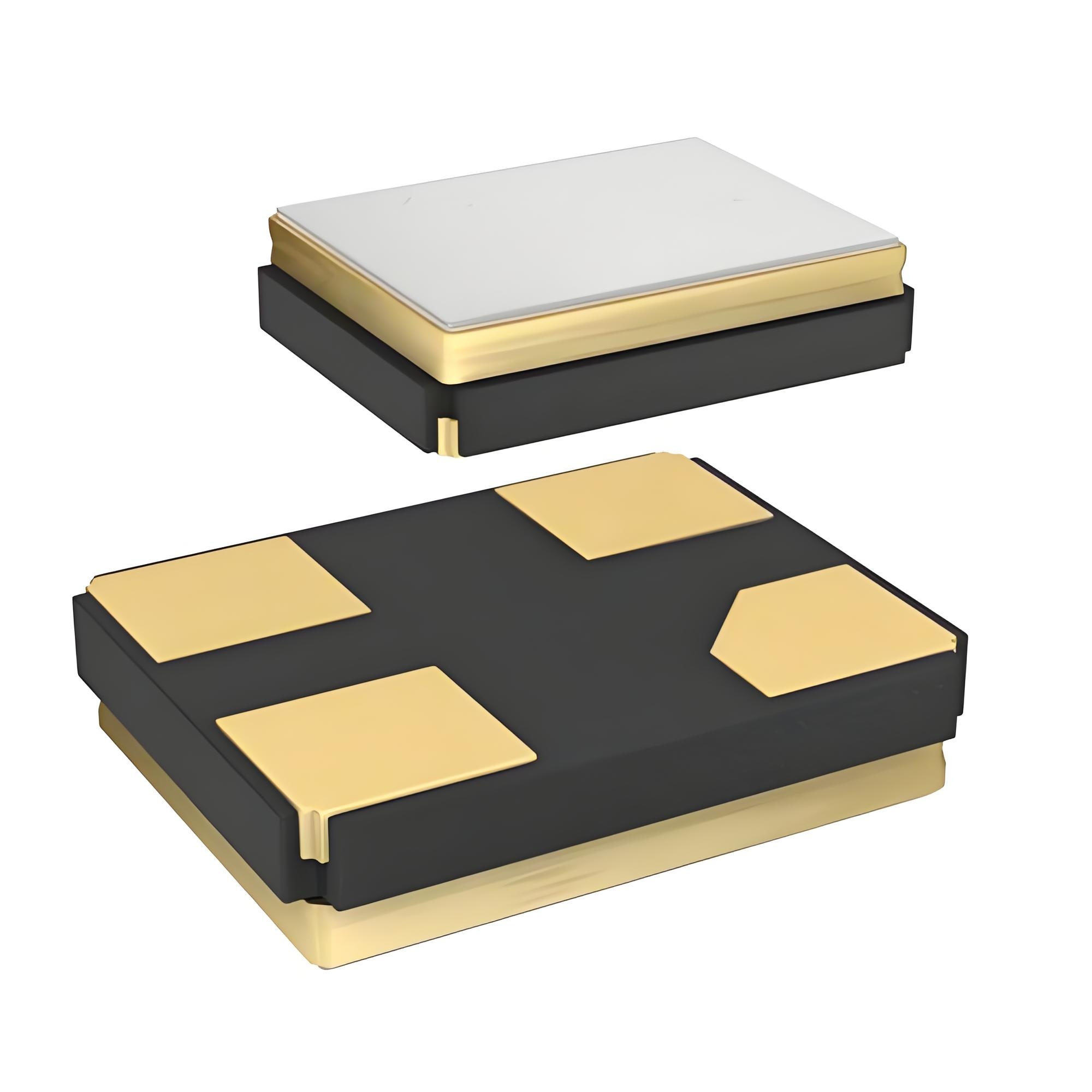

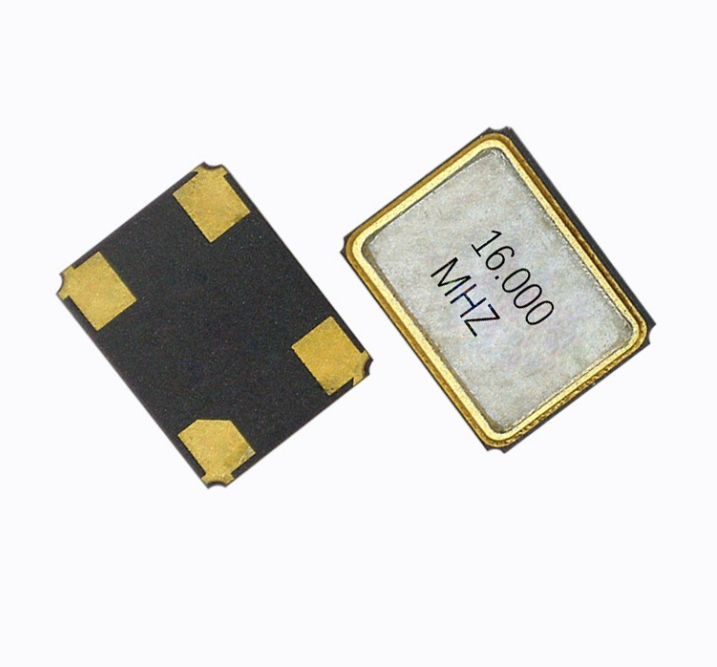

The S32 Series of crystal oscillators, specifically the SMD Quartz Crystal Resonator S32 Series, offers notable advancements in accuracy and reliability, making them indispensable in various technological sectors.

The S32 Crystal Oscillator is designed with a focus on high precision and reliability, critical traits for applications where timing accuracy is paramount. Frequency stability, measured in parts per million (PPM), reflects the oscillator's precision. In the case of the S32 Crystal Oscillator, frequency deviations are minimal, typically within a range of ±10 PPM to ±30 PPM. This level of accuracy ensures that even under varying environmental conditions such as temperature and pressure, the oscillator maintains its stability.

In industries like telecommunications and automotive, maintaining precise timing is crucial for ensuring that communication signals are in sync and data transmission is flawless. The S32 crystal's ability to operate at such high levels of accuracy is one reason it's used in these high-tech industries.

While the S32 Crystal Oscillator is engineered for precision, several external factors can influence its performance:

Temperature: Temperature variations can have a significant impact on crystal oscillators. However, the S32 Series includes temperature-compensated models that help reduce frequency drift over a wide temperature range. This is essential in automotive applications where temperature fluctuations are common.

Aging: Over time, crystal oscillators experience slight changes in frequency, known as aging. The S32 Crystal Oscillator is built with durable materials to minimize aging effects, ensuring long-term reliability.

Load Capacitance: The load capacitance can also affect the oscillator's frequency. The S32 Crystal Oscillator is optimized for standard load capacitance, reducing the risk of frequency deviations in different circuit configurations.

Beyond accuracy, the S32 Crystal Oscillator is recognized for its long-term stability. Oscillators in general may face frequency drift over time due to environmental stress, but the S32's robust design counters this, making it a reliable choice for long-duration applications like in automotive electronics where consistency is critical for safety and performance.

Additionally, the oscillator's S3225 Crystal OEM Factory version, with its surface-mount device (SMD) packaging, enhances its reliability in compact designs, enabling it to be used effectively in space-constrained devices such as smartphones and wearables.

The use of crystal oscillators like the S32 is widespread across various sectors. Here are a few critical applications where the S32 Crystal Oscillator's high precision and reliability shine:

Telecommunications: In telecommunications systems, the accuracy of signal transmission is paramount. The S32 oscillator ensures that frequency shifts are minimal, preventing miscommunication or data loss. These oscillators are often found in network timing systems, base stations, and data transmission hardware.

Automotive Electronics: The automotive industry demands components that can endure harsh environmental conditions while maintaining precise performance. In systems such as navigation, engine control units (ECUs), and advanced driver-assistance systems (ADAS), the S32 oscillator ensures that systems run accurately and efficiently.

Consumer Electronics: In devices like smartphones, smartwatches, and gaming consoles, maintaining accurate timing is crucial for functionality. The compact and reliable design of the S32 oscillator is ideal for these electronics, where size, weight, and energy consumption are all concerns.

SMD Quartz Crystal Resonator S32 Series: A Key to High Performance

One of the main advantages of the SMD Quartz Crystal Resonator S32 Series is its surface-mount technology (SMT) design, which allows it to be easily integrated into modern electronic circuits. SMT devices are compact, efficient, and cost-effective for mass production, making them ideal for consumer electronics and automotive industries.

Moreover, the small size of the S3225 Crystal (3.2mm x 2.5mm) makes it compatible with designs that require minimal space without compromising on performance. Its reduced size allows for the development of thinner and lighter products, a critical factor in industries focused on miniaturization.

In conclusion, the S32 Crystal Oscillator is a highly accurate and reliable component that plays a vital role in ensuring the correct timing and synchronization in various electronic systems. Its stable frequency, resistance to environmental influences, and long-term reliability make it an ideal choice for demanding applications in telecommunications, automotive, and consumer electronics.

When considering a crystal oscillator for your project, the S32 Series stands out due to its proven high precision and ability to meet the demands of advanced technological systems. The combination of precision, stability, and durability ensures that the S32 Crystal Oscillator remains an industry-leading solution for electronic applications.You can send your request to this email ivy@jghcrystal.com and we will contact you within 24 hours.

Read More