What are the Criteria for Crystal Oscillator Selection?

Oct 30, 2024

Crystal oscillators are essential components in electronics, serving as highly stable frequency sources for a wide range of applications—from communication devices to computer systems and precision timekeeping. Selecting the right crystal oscillator for a specific application requires understanding various parameters that define its performance. We will walk you through the key parameters of a crystal oscillator, including frequency range, load capacitance, frequency tolerance, and operating temperature range, and explain how each factor affects the overall performance of the device.

Choosing a crystal oscillator involves evaluating its technical specifications and how they align with the operational requirements.

Frequency RangeThe crystal oscillator frequency range specifications define the range within which the oscillator can generate frequencies reliably. Oscillators are generally designed to operate within a specific range, and selecting the right frequency is crucial for ensuring synchronization with other electronic components.

Lower Frequencies (up to 100 kHz): Used in applications such as clocks and watches, these oscillators offer high stability and low power consumption.

Mid-Range Frequencies (1 MHz to 30 MHz): Commonly used in communication devices and microcontrollers, oscillators in this range provide a balance of performance and power efficiency.

High Frequencies (up to hundreds of MHz): These are used in high-speed processors, network communication, and radio frequency (RF) applications.

Selecting the right frequency range depends on the application's specific needs and ensures the crystal oscillator can handle the intended frequency without issues such as distortion or phase noise.

Load CapacitanceLoad capacitance represents the total capacitance in the oscillator's circuit, impacting the accuracy of the crystal's frequency. It is defined as the capacitance seen by the crystal from the circuit it is connected to.

Impact on Frequency Stability: A mismatch in load capacitance can cause frequency shifts, reducing the oscillator's stability and potentially causing malfunctions in sensitive applications.

Application-Specific Load Capacitance: Typically, for applications needing high accuracy, such as RF communication, a carefully matched load capacitance is necessary to prevent frequency drift.

Understanding the impact of load capacitance on crystal oscillator performance is essential when selecting a crystal oscillator, as even minor variances in capacitance can lead to inaccuracies.

Frequency ToleranceFrequency tolerance refers to the acceptable deviation from the specified frequency, usually represented as a percentage. This parameter is crucial for applications where even slight deviations could result in significant performance issues.

Tolerance Levels: The tolerance level is typically specified at room temperature and might vary with changes in operating conditions.

Application-Based Tolerances: For example, communication systems that rely on precise timing, such as GPS or Wi-Fi, require tight tolerances (e.g., ±10 ppm) to maintain accuracy and reliability. However, applications with lower precision requirements may accommodate wider tolerances.

Understanding frequency tolerance in crystal oscillators helps in selecting an oscillator that matches the required accuracy, ensuring consistent and reliable performance in critical applications.

Operating Temperature RangeThe operating temperature range for crystal oscillators specifies the range of temperatures within which the oscillator can function effectively. Temperature variations impact the crystal's frequency, so oscillators are designed to accommodate specific environmental conditions.

Common Ranges: Standard crystal oscillators typically operate between -10°C to 60°C, while industrial-grade oscillators can handle -40°C to 85°C. Specialized oscillators for extreme conditions may operate from -55°C to 125°C.

Thermal Stability: Oscillators used in environments with extreme temperature fluctuations, such as automotive or aerospace applications, require a wider operating temperature range to maintain stability across these conditions.

Selecting an oscillator with an appropriate temperature range ensures it can handle the operational environment without compromising frequency stability or durability.

Additional Factors Influencing Crystal Oscillator Performance

In addition to the primary crystal oscillator parameters mentioned above, several other factors influence the oscillator's performance and selection:

Aging: Over time, oscillators experience slight frequency drift, known as aging. Applications requiring long-term stability, such as time-keeping devices, may require oscillators with low aging rates.

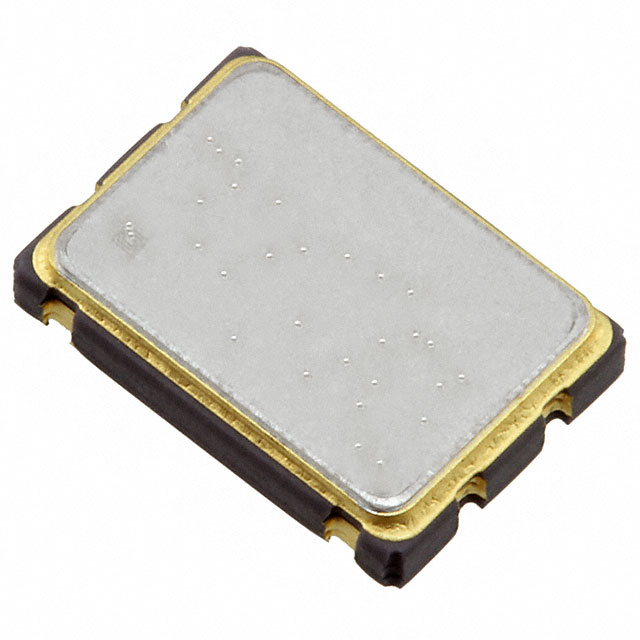

Package Type: Crystal oscillators come in various package types, such as through-hole and surface-mount packages. The choice depends on the assembly process and size constraints of the application.

Drive Level: This parameter refers to the amount of power applied to the crystal. Maintaining an appropriate drive level prevents the crystal from overheating and ensures consistent performance.

How to Select a Crystal Oscillator for Specific Applications

Choosing the right crystal oscillator involves matching the application's requirements with the oscillator's specifications.

Determine the Required Frequency RangeIdentify the operating frequency that the application needs. This ensures the oscillator can operate within the required range and deliver reliable performance. For example, an oscillator for a microcontroller will have different frequency requirements than one used in RF communication.

Match Load Capacitance with Circuit DesignVerify that the oscillator's load capacitance aligns with the circuit's requirements to prevent frequency deviation. Ensuring a proper match is particularly important in precision applications, such as timing in communication devices.

Specify Frequency Tolerance Based on Application NeedsChoose a frequency tolerance that aligns with the required accuracy. Applications with tight timing demands, such as GPS, benefit from high tolerance specifications to maintain reliability.

Ensure Adequate Operating Temperature RangeBased on the intended operating environment, select an oscillator with a suitable temperature range. For instance, outdoor or automotive applications, which face varying temperatures, require oscillators that maintain frequency stability across a wide temperature range.

Evaluate Additional Requirements (Aging, Drive Level, Package Type)Consider the long-term stability, appropriate power levels, and packaging needed for assembly to ensure the oscillator meets all design and durability requirements.

Understanding the Relationship Between Parameters and Performance

The crystal oscillator frequency range specifications, load capacitance, frequency tolerance, and temperature range are interrelated and influence the oscillator's overall performance.

Load Capacitance and Frequency Accuracy: Load capacitance affects the crystal's resonant frequency, making it essential to balance capacitance to maintain accuracy.

Temperature Range and Frequency Tolerance: Temperature fluctuations cause frequency shifts. Selecting an oscillator with the right temperature range minimizes frequency drift and maintains tolerance levels.

Drive Level and Frequency Stability: Excessive drive levels can damage the crystal, leading to instability. Ensuring an appropriate drive level maintains long-term stability.

Selecting a crystal oscillator requires a comprehensive understanding of its key parameters, including frequency range, load capacitance, frequency tolerance, and operating temperature range. By aligning these parameters with the application's requirements, manufacturers and engineers can ensure that the oscillator performs reliably under specified conditions. Each parameter affects the oscillator's stability and accuracy, making it essential to carefully evaluate these factors for optimal performance across different applications. With the right selection approach, a crystal oscillator can provide stable and precise frequency control, meeting the demands of modern electronics and high-precision environments.Shenzhen Jingguanghua Electronics Co., Ltd. has a professional R&D and engineering technology team to provide customers with full technical services and support before, during and after sales. If you have product needs, please send an email to ivy@jghcrystal.com, and we will provide you with the most professional solution.

Read More